Why Effective Logistics Inventory Management Is Crucial for Business Success

In today's highly competitive business landscape, effective logistics inventory management is not just an operational necessity but a crucial determinant of overall success. According to a recent report by the Council of Supply Chain Management Professionals (CSCMP), efficient inventory management can lead to a reduction of up to 25% in operational costs, highlighting its significant impact on profitability. The need for precision and responsiveness in the supply chain has never been more pronounced, as businesses strive to meet customer demands while minimizing excess inventory and associated carrying costs.

Industry expert Dr. Jane Smith, a leading authority in logistics and supply chain optimization, emphasizes, "An organization’s ability to manage its inventory effectively is directly linked to its agility in responding to market changes." Her insights underscore the importance of leveraging advanced logistics inventory management strategies that incorporate data analytics, technological innovation, and a customer-centric approach. As companies look to enhance their operational prowess, mastering the intricacies of logistics inventory management will be essential for sustaining competitive advantage and fulfilling consumer expectations in a rapidly evolving market.

Understanding the Importance of Logistics Inventory Management

Effective logistics inventory management plays a pivotal role in the success of any business. It involves the meticulous planning, controlling, and monitoring of the flow of goods from the point of origin to the final customer. An efficient inventory management system ensures that products are available when needed, reducing the risk of stockouts or overstock situations that can hinder operational efficiency. By maintaining optimal inventory levels, businesses can better respond to customer demands and market fluctuations, ultimately enhancing overall customer satisfaction.

Moreover, understanding the importance of logistics inventory management extends beyond simply keeping track of stock. It encompasses strategic decision-making that influences various aspects of a business, from warehouse operations to transportation efficiency. A well-implemented inventory management strategy helps companies minimize holding costs, optimize storage space, and streamline their supply chain processes. This not only leads to reduced operational costs but also allows for more agile business operations, positioning companies to take advantage of emerging opportunities in a competitive marketplace.

Why Effective Logistics Inventory Management Is Crucial for Business Success

| Inventory Management Aspect | Importance | Impact on Business |

|---|---|---|

| Stock Accuracy | Reduces discrepancies between recorded and actual stock | Improves customer satisfaction and sales potential |

| Lead Time Management | Optimizes delivery schedules and inventory replenishment | Reduces stockouts and excess inventory costs |

| Demand Forecasting | Estimates future product requirements | Helps in maintaining optimal stock levels |

| Supplier Relationships | Cultivates reliable partnerships for timely supply | Enhances supply chain efficiency and performance |

| Technology Integration | Utilizes software for tracking and managing inventory | Increases operational efficiency and reduces errors |

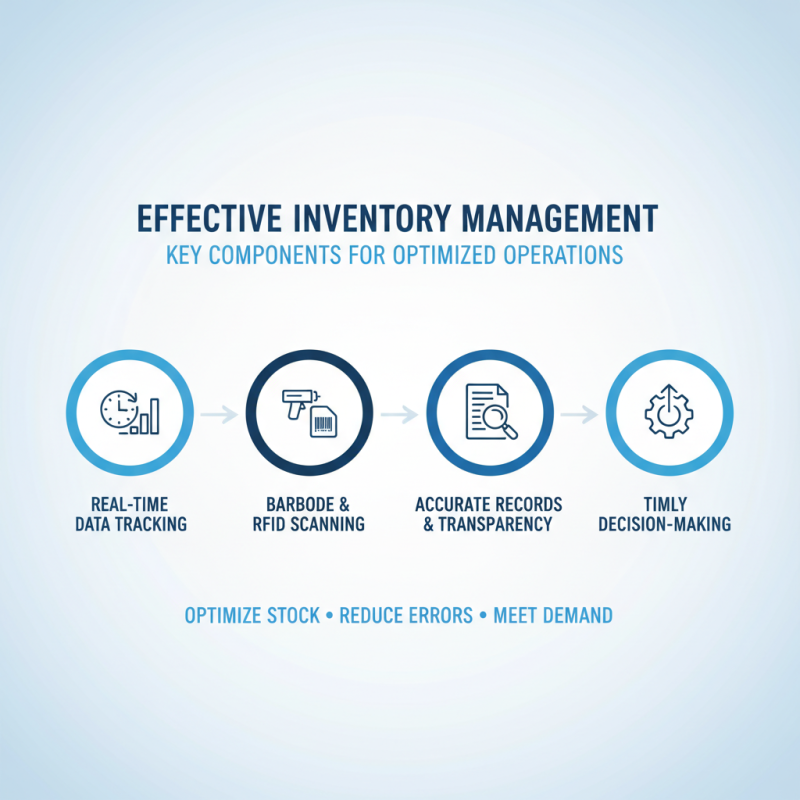

Key Components of Effective Inventory Management Systems

Effective inventory management systems are built on several key components that ensure businesses can optimize their operations and meet customer demands. One essential element is real-time data tracking, which allows companies to monitor stock levels, sales patterns, and lead times. Implementing technologies such as barcode scanning and RFID helps in minimizing errors and enhances accuracy in inventory records. This transparency in inventory status facilitates timely decision-making, ensuring that businesses can respond swiftly to fluctuations in demand without overstocking or running out of critical items.

Another important component is demand forecasting, which leverages historical sales data and market trends to predict future inventory needs. By accurately anticipating demand, businesses can streamline their purchasing and production processes, reducing holding costs and improving cash flow. Additionally, integrating inventory management with supply chain logistics plays a vital role in enhancing efficiency. This coordination helps in aligning supply with demand, ensuring that products are available when needed and reducing the risk of excess stock. Collectively, these components enable organizations to build a resilient inventory management strategy that not only supports operational efficiency but also enhances customer satisfaction and business success.

Strategies for Optimizing Inventory Levels and Reducing Costs

Effective logistics inventory management is vital for businesses aiming to enhance efficiency and reduce operational costs. According to a study by the Council of Supply Chain Management Professionals, companies that invest in inventory optimization can lower their logistics costs by 20% to 30%.

One crucial strategy for optimizing inventory levels involves implementing just-in-time (JIT) inventory practices. This approach not only minimizes excess stock but also ensures that businesses have the necessary materials on hand when needed, reducing holding costs associated with overstocked inventory.

Another effective strategy is utilizing demand forecasting tools. Advanced analytics and machine learning algorithms enable businesses to predict inventory needs more accurately based on historical data and market trends. A report from Deloitte suggests that organizations leveraging such tools can reduce stockouts by 50% and decrease excess inventory by 30%. By aligning inventory levels closely with actual demand, businesses can enhance customer satisfaction through improved service levels while simultaneously decreasing warehousing costs. In a competitive marketplace, these strategies are essential for achieving superior inventory management outcomes that support overall business success.

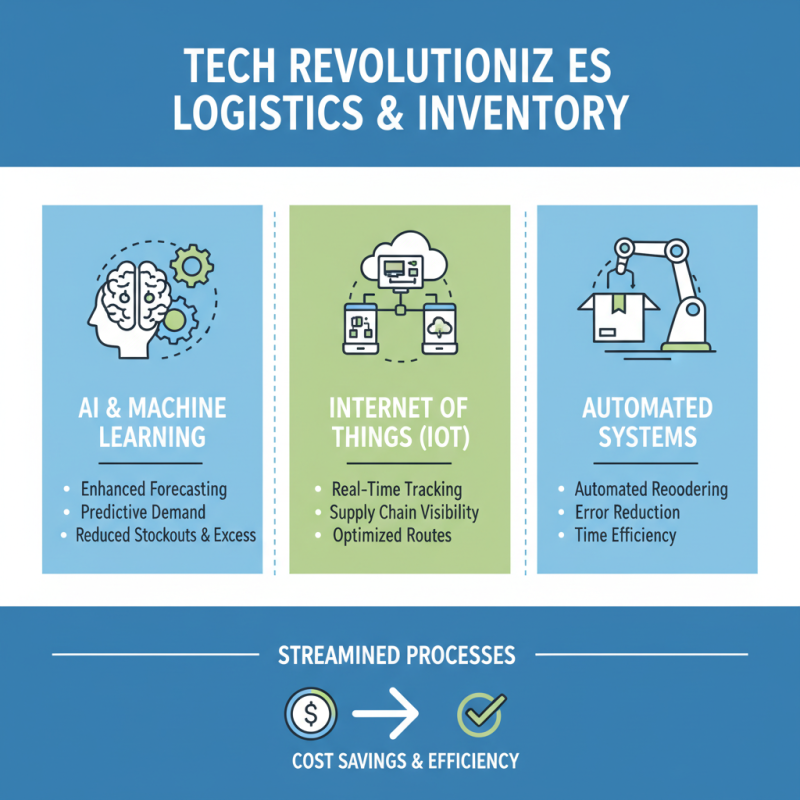

Impact of Technology on Logistics and Inventory Management

The impact of technology on logistics and inventory management has been profound, revolutionizing the way businesses operate. Advanced technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) have streamlined processes, enabling real-time tracking and optimized inventory levels. These technologies facilitate enhanced forecasting methods that allow businesses to predict demand more accurately, thereby reducing excess stock and minimizing shortages. Automated systems can reorder inventory without human intervention, drastically cutting down on time and reducing the potential for errors associated with manual processes.

Moreover, the integration of technology has transformed warehousing and distribution. Automated warehousing solutions, including robotics and autonomous vehicles, have sped up the retrieval and shipping processes. This not only enhances efficiency but also improves accuracy in inventory management. Businesses can now analyze data insights to further refine their logistics strategies, ensuring that products are delivered in a timely manner to meet customer expectations. Consequently, the adoption of technology in logistics and inventory management does not merely enhance operational efficiency but also plays a pivotal role in fostering stronger customer relationships and driving business growth.

Challenges and Solutions in Modern Inventory Management Practices

Inventory management is a critical component of logistics that directly impacts a business’s success, yet many organizations face substantial challenges in optimizing their inventory practices. According to a report by the Council of Supply Chain Management Professionals (CSCMP), poor inventory management can lead to excess stock, which ties up cash flow, and stockouts, which result in lost sales opportunities. Companies that fail to address these issues may experience a decrease in customer satisfaction and a significant dip in competitive advantage. In fact, a survey conducted by Deloitte revealed that 79% of organizations with high-performing supply chains achieve revenue growth superior to the average within their industries.

Modern inventory management practices are evolving, driven by technological advancements and the need for increased efficiency. However, challenges persist, such as the complexity of demand forecasting and the integration of inventory management systems with other supply chain processes. According to a study by McKinsey, businesses that leverage advanced analytics and real-time data can enhance their inventory accuracy by up to 30%, which significantly minimizes excess stock and stockouts. Furthermore, utilizing cloud-based inventory solutions enables companies to gain better visibility into their stock levels across various locations, leading to more informed decision-making. Therefore, embracing innovative inventory management practices is essential for businesses striving to enhance operational efficiency and achieve long-term success.

Related Posts

-

Top 10 Inventory Management Solutions to Streamline Your Business Operations

-

10 Essential Tips for Choosing the Right Logistics Partner for Your Business

-

2025 Top 5 Trends Shaping the Future of Supply Chain Management

-

2025 Top Logistics Business Trends and Digital Innovations to Watch

-

2025 How to Choose the Best Logistics Solutions for Your Business

-

How to Start a Successful Logistics Business in 2023 Tips and Strategies