Understanding Order Fulfillment Services: Key Benefits and Best Practices

In today’s rapidly evolving e-commerce landscape, businesses are increasingly recognizing the critical role that order fulfillment services play in driving customer satisfaction and operational efficiency. According to a report by the National Retail Federation, approximately 75% of retailers in the United States view logistics as a vital element of their competitive strategy, emphasizing the importance of effective order fulfillment processes. The demand for streamlined order fulfillment solutions has surged as consumers expect faster shipping times and improved order accuracy, with studies indicating that 30% of customers are willing to pay more for same-day delivery options.

Moreover, research by Statista highlights that the global market for order fulfillment services is projected to exceed $75 billion by 2024, driven by exponential growth in online shopping and increased consumer expectations for delivery services. As companies strive to keep pace with these trends, understanding the key benefits and best practices of order fulfillment services becomes essential. Implementing efficient fulfillment strategies not only enhances customer loyalty but also optimizes supply chain operations, making it imperative for businesses to explore innovative fulfillment solutions that cater to the needs of the modern consumer.

Understanding the Concept of Order Fulfillment Services

Order fulfillment services play a pivotal role in the modern e-commerce landscape, enabling businesses to efficiently manage their inventory, shipping, and returns processes. The concept revolves around the systematic handling of customer orders from the moment they are placed until the product reaches the end consumer. According to a report by the Logistics Management Association, around 79% of consumers indicate that the speed of order fulfillment significantly influences their purchasing decisions. This underscores the importance of timely and accurate order processing in enhancing customer satisfaction and loyalty.

The adoption of effective order fulfillment services can lead to significant cost reductions and operational efficiency. Research from the National Retail Federation highlights that companies utilizing third-party logistics for order fulfillment can reduce logistics costs by 20-30% compared to handling processes in-house. Best practices in order fulfillment emphasize automation and inventory management systems, which help businesses accurately track stock levels and forecast demand. By leveraging these technologies, companies can minimize errors, improve operational speed, and ultimately meet consumer expectations in an increasingly competitive market.

Key Benefits of Outsourcing Order Fulfillment to Third-Party Providers

Outsourcing order fulfillment to third-party providers offers a range of advantages that can significantly enhance a business's operational efficiency. One of the primary benefits is cost reduction. By leveraging the expertise and resources of specialized fulfillment centers, businesses can avoid the overhead costs associated with maintaining their own warehouses and hiring staff. This can lead to improved cash flow and allow companies to reinvest savings into other critical areas of their operations, such as marketing and product development.

Another significant advantage is the scalability that third-party fulfillment services provide. As businesses experience seasonal fluctuations in demand or rapid growth, they can easily adjust their fulfillment strategies without the need for lengthy transition periods or significant capital investments. Third-party providers typically have advanced systems in place that can accommodate varying order volumes, ensuring that businesses can meet customer expectations without compromising on service quality.

Additionally, these providers often have access to a wider range of technologies and logistics networks, enabling a more efficient and reliable delivery process. This flexibility not only streamlines operations but also enhances customer satisfaction, a crucial factor in retaining clients in a competitive marketplace.

Best Practices for Efficient Order Processing and Inventory Management

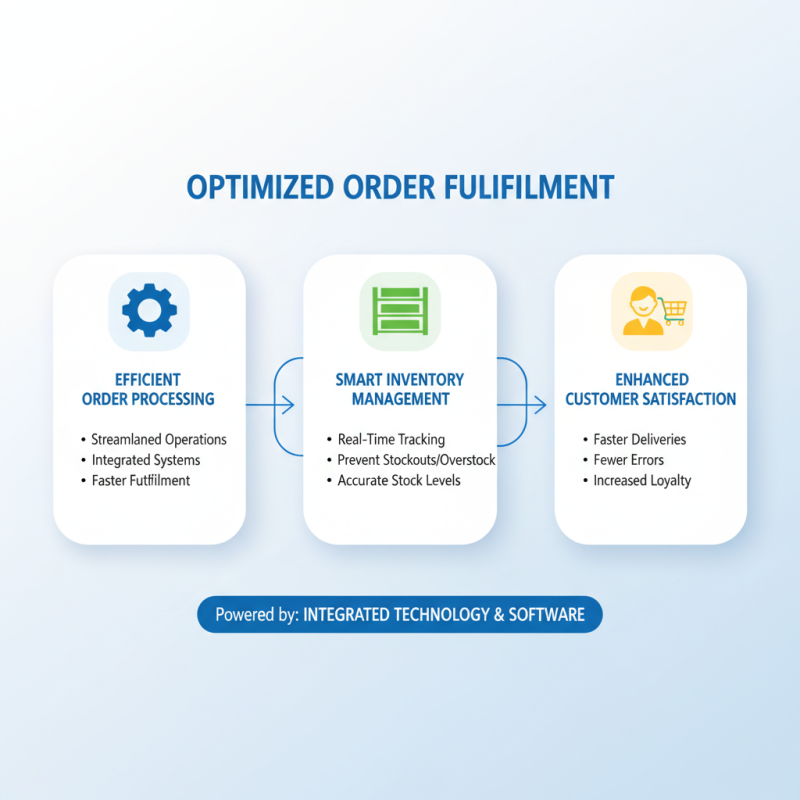

Efficient order processing and inventory management are vital components of successful order fulfillment services. To streamline operations, businesses should implement systems that integrate inventory tracking with order processing. By utilizing technology like inventory management software, companies can gain real-time visibility of stock levels, which helps prevent stockouts and overstock situations, ultimately enhancing customer satisfaction.

Tips: Always maintain a buffer stock for high-demand items to handle unexpected surges in orders. This practice ensures that you are prepared for fluctuations in consumer behavior without compromising delivery times.

Additionally, optimizing your picking and packing processes can greatly improve efficiency. Automation tools, such as barcode scanners and packing machines, can reduce manual errors and speed up order fulfillment. This efficiency not only saves time but also minimizes labor costs, making your operations more profitable.

Tips: Organize your warehouse layout strategically by placing fast-moving items closer to packing stations. This reduces the time employees spend retrieving products, leading to quicker order processing and enhanced productivity.

Integrating Technology into Order Fulfillment for Enhanced Performance

Integrating technology into order fulfillment services has become a pivotal strategy for businesses looking to enhance their operational performance and improve customer satisfaction. According to a report by McKinsey, companies that invest in advanced technology for their fulfillment processes can reduce fulfillment costs by up to 30%. Automation technologies, such as robotic picking systems and AI-driven inventory management, streamline operations, minimize human error, and accelerate order processing times. This not only enhances efficiency but also contributes to a more responsive supply chain, enabling businesses to meet consumer demands swiftly.

Moreover, adopting integrated software solutions allows for real-time tracking and data analytics, which are crucial for optimizing inventory levels and forecasting demand. A survey by the eCommerce Foundation found that 67% of consumers expect their orders to be delivered within two days, showcasing the importance of quick and accurate fulfillment. By leveraging technologies such as cloud-based systems and Internet of Things (IoT) devices, businesses can gain better visibility into their logistics processes, leading to improved decision-making and increased customer satisfaction. Ultimately, the integration of technology in order fulfillment is not merely an option but a necessity for companies aiming to thrive in today's competitive marketplace.

Order Fulfillment Services Performance Metrics

Measuring Success: Key Performance Indicators for Fulfillment Services

Measuring the success of fulfillment services hinges on a set of key performance indicators (KPIs) that provide insights into efficiency and customer satisfaction. According to a recent industry report by the Warehousing Education and Research Council, the order fulfillment accuracy rate is crucial, with leading companies reporting an accuracy level of over 99%. This metric not only reflects the operational prowess of fulfillment providers but also plays a significant role in preserving customer trust and loyalty. Businesses that maintain a high accuracy rate tend to see a 30% increase in repeat purchases, emphasizing the importance of minimizing errors in the fulfillment process.

Another essential KPI is the average order turnaround time, which includes the time taken from order placement to delivery. Research by the International Warehouse Logistics Association shows that companies with a turnaround time under 24 hours can achieve up to 20% higher customer satisfaction rates compared to those taking longer. Efficient logistics and inventory management systems are critical to achieving these timeframes, allowing businesses to respond swiftly to customer demands, especially in today’s fast-paced e-commerce environment. Monitoring these KPIs regularly enables fulfillment services to identify areas for improvement, ultimately enhancing overall operational effectiveness.

Understanding Order Fulfillment Services: Key Benefits and Best Practices - Measuring Success: Key Performance Indicators for Fulfillment Services

| KPI | Description | Target Value | Current Value | Notes |

|---|---|---|---|---|

| Order Accuracy | Percentage of orders fulfilled correctly | 99% | 98% | Needs improvement |

| Order Cycle Time | Average time taken from order placement to delivery | 24 hours | 30 hours | Consider optimizing logistics |

| Inventory Turnover | Rate at which inventory is sold and replaced | 5 times/year | 4 times/year | Stock management improvements needed |

| Return Rate | Percentage of orders returned by customers | 5% | 7% | Analyze reasons for returns |

| Customer Satisfaction Score | Measure of how products and services meet customer expectations | 85% | 80% | Surveys needed for feedback |

Related Posts

-

10 Essential Tips for Choosing the Right Logistics Partner for Your Business

-

Top 10 Inventory Management Solutions to Streamline Your Business Operations

-

Top 10 Warehousing Companies Revolutionizing Supply Chain Efficiency in 2023

-

2025 How to Choose the Best Logistics Solutions for Your Business

-

How to Start a Successful Logistics Business in 2023 Tips and Strategies

-

2025 Top Logistics Business Trends and Digital Innovations to Watch