What is Supply Chain Management Solutions and How Do They Work?

In today's global market, efficient supply chain management solutions are crucial for business success. Experts like Dr. Jane Smith, a prominent figure in this field, emphasize, "Effective supply chain management can transform a company's operational capabilities." Her words highlight the significance of these solutions in enhancing productivity.

Supply chain management solutions encompass various strategies and technologies. They streamline processes, reduce costs, and improve customer satisfaction. However, many companies struggle with implementation. Without a clear understanding, businesses may face delays and inefficiencies. It’s essential for organizations to reassess their approaches to these solutions regularly.

The importance of real-time data in supply chain management cannot be overstated. Access to accurate information allows for better decision-making. Yet, many still rely on outdated methods. This gap can lead to missed opportunities and lost revenue. A reflection on past mistakes can pave the way to more effective supply chain management solutions.

Definition of Supply Chain Management Solutions

Supply chain management solutions are essential for efficiency in today's interconnected market. They integrate various processes, from sourcing to distribution. Understanding how these solutions work involves knowing their core components. According to a report by Gartner, companies that effectively manage their supply chains can reduce operational costs by 15% or more. This highlights the importance of logistics and inventory management.

The definition of supply chain management solutions includes tools that enhance visibility and control. For example, technology like predictive analytics can forecast demand, minimizing overstock situations. A study by Deloitte found that 79% of companies with high-performing supply chains achieve revenue growth. However, many firms struggle with issues like data silos and communication gaps. These weaknesses can lead to inefficiencies and lost sales.

Investing in targeted supply chain management solutions can be challenging. Organizations must evaluate their needs and capabilities. As noted in recent industry research, 40% of businesses experience significant disruptions each year. These disruptions often stem from inadequate planning or outdated technology. Addressing these shortcomings can lead to improved resilience and flexibility, crucial for staying competitive.

Key Components of Supply Chain Management Solutions

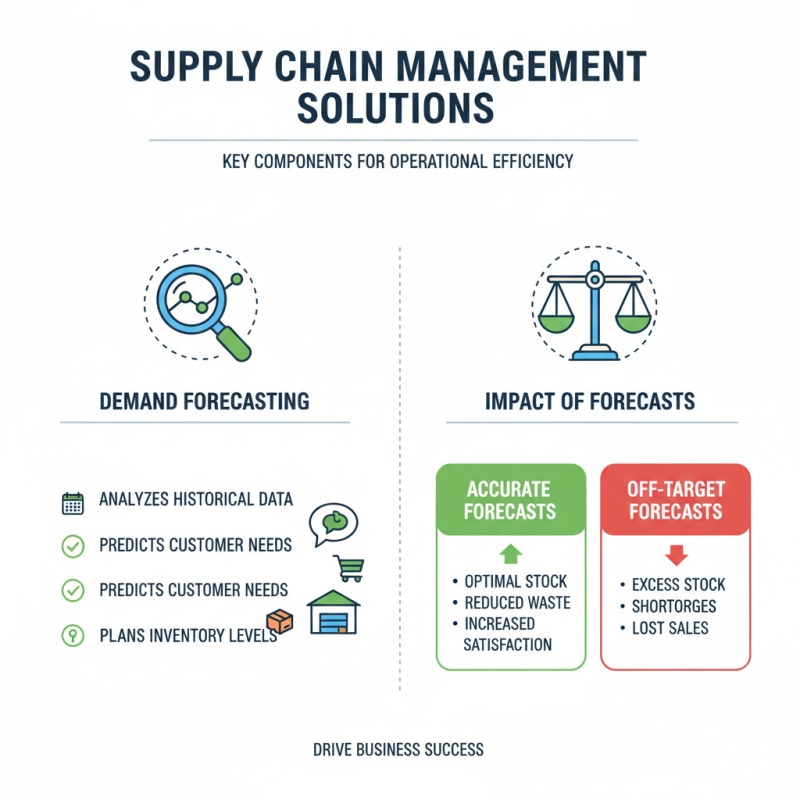

Supply Chain Management Solutions consist of various key components that enhance efficiency in operations. One of the crucial elements is demand forecasting. This involves analyzing historical data to predict customer needs. Accurate forecasts help businesses plan inventory levels effectively. However, they can sometimes be off the mark, leading to excess stock or shortages.

Another important component is logistics management. This includes transportation, warehousing, and distribution. Efficient logistics ensure timely delivery of products. Yet, managing logistics can be complex. Delays due to unforeseen circumstances can disrupt the entire supply chain. Organizations must continuously evaluate their logistics strategies to minimize risks.

Supplier relationship management also plays a vital role. Building strong partnerships with suppliers helps in securing better prices and quality. However, trust can be a delicate issue. A lack of transparency might harm these relationships. Therefore, companies need to prioritize open communication with suppliers. These components, while often effective, require constant monitoring and adjustment to truly succeed.

How Supply Chain Management Solutions Improve Efficiency

Supply Chain Management (SCM) solutions enhance efficiency by streamlining processes. According to the 2022 SCM Institute report, companies using SCM tools can improve their operational efficiency by up to 25%. These tools automate tasks, reducing manual errors and speeding up order fulfillment.

Efficient SCM solutions also contribute to better inventory management. The Gartner Supply Chain Top 25 report highlights that businesses can reduce inventory costs by approximately 30% with effective SCM practices. This not only lowers storage costs but also helps avoid stockouts and overstock situations. Improved visibility through SCM tools allows companies to track their inventory in real-time.

Despite these benefits, challenges remain. Many companies struggle to integrate new SCM solutions with existing systems. In fact, 40% of organizations report difficulties in achieving seamless integration. This gap often leads to a temporary dip in productivity as employees adjust to new processes. Additionally, not all employees may be trained adequately, which can hinder the potential of these solutions.

Types of Supply Chain Management Solutions Available

Supply Chain Management (SCM) solutions come in various types, each serving a unique purpose. One common type is supply chain planning software. This tool helps businesses forecast demand and manage inventory. It uses historical data to align production with customer needs. However, predictions aren't always accurate. A sudden change in market demand can still disrupt even the best-laid plans.

Another essential type is transportation management systems (TMS). These solutions streamline the logistics of moving goods from one place to another. They help manage routes, carriers, and shipping paperwork. Yet, relying solely on technology can lead to oversights. Human errors or unexpected incidents, like traffic, can complicate delivery schedules.

Finally, warehouse management solutions optimize storage and inventory processes. They manage stock levels and location within warehouses. Properly organized warehouses can boost efficiency. Still, complexities arise when dealing with diverse product types. Balancing space and inventory levels can be challenging. As systems evolve, continuous assessment and adaptation are necessary to address these imperfections.

Supply Chain Management Solutions Overview

This bar chart illustrates the various types of Supply Chain Management Solutions and their adoption rates among organizations. The data represents a survey conducted in 2023.

The Role of Technology in Supply Chain Management Solutions

Technology plays a crucial role in supply chain management solutions. It helps streamline processes and improve efficiency. Advanced software allows businesses to track inventory in real-time. Automated systems can reduce human error and enhance accuracy. This technology creates a more responsive supply chain.

Data analytics is another key element. Businesses can analyze trends and forecast demand. However, the reliance on data can lead to pitfalls. For example, poor data quality can misguide decision-making. Companies must continually refine their data collection methods to avoid these issues.

Integration of various technologies like AI and IoT also shifts supply chain dynamics. AI predicts inventory needs, while IoT devices monitor equipment conditions. However, there is a challenge in ensuring compatibility among different systems. Conflicting technologies can slow down operations, making it vital to choose the right tools. Finding this balance is a complex yet necessary task.

What is Supply Chain Management Solutions and How Do They Work? - The Role of Technology in Supply Chain Management Solutions

| Dimension | Description | Technology Involved | Benefits |

|---|---|---|---|

| Inventory Management | Overseeing stock levels and order management | RFID, IoT Sensors | Optimized stock levels, reduced carrying costs |

| Order Processing | Managing customer orders from receipt to fulfillment | CRM Systems, Automation Software | Faster order fulfillment, improved customer satisfaction |

| Supplier Collaboration | Working closely with suppliers for better procurement | Supply Chain Platforms, Communication Tools | Enhanced supplier relationships, better pricing |

| Logistics Management | Coordinating the transportation of goods | GPS, Route Optimization Software | Reduced shipping costs, improved delivery times |

| Forecasting and Planning | Predicting demand to align supply | AI, Data Analytics | Improved demand accuracy, reduced stockouts |

Related Posts

-

2025 How to Choose the Best Logistics Solutions for Your Business

-

Why Effective Supply Chain Management is Crucial for Business Success

-

Top 10 Tips for Optimizing Order Fulfillment to Boost Your Business Efficiency

-

How to Choose the Best Inventory Solutions for Your Business Needs

-

Why Order Fulfillment is Crucial for Your Business Success?

-

Top 10 Inventory Management Solutions to Streamline Your Business Operations