Top 10 Tips for Optimizing Order Fulfillment to Boost Your Business Efficiency

In today's highly competitive business landscape, effective order fulfillment is crucial for driving operational efficiency and enhancing customer satisfaction. As e-commerce continues to expand, companies are tasked with the challenge of delivering products promptly and accurately to meet the growing expectations of consumers. This has made streamlining order fulfillment processes not just a necessity, but a strategic component that can significantly impact a business's success.

To succeed in this dynamic environment, it is essential for organizations to implement best practices in order fulfillment that can lead to improved efficiency and reduced operational costs. By examining the top ten tips for optimizing order fulfillment, businesses can identify opportunities for enhancement in their logistics, inventory management, and customer service. By focusing on these areas, companies not only improve their internal processes but also create a more satisfying purchasing experience for their customers, ultimately leading to increased loyalty and repeat business. Let's delve into these transformative strategies that can propel your order fulfillment efforts to new heights.

Understanding the Order Fulfillment Process for Business Success

Understanding the order fulfillment process is crucial for any business aiming to enhance its efficiency and customer satisfaction. This process typically encompasses several key stages:

order receipt, processing, inventory management, packing, and shipping. By mastering each step, businesses can streamline operations, reduce errors, and ensure timely delivery, which are essential for maintaining a competitive edge in the market.

Effective inventory management is vital in the order fulfillment process. Businesses must maintain optimal stock levels to prevent delays or shortages that can adversely affect customer experience. Implementing real-time tracking systems allows businesses to monitor inventory levels accurately and predict demand trends.

Additionally, automating the order processing phase can lead to faster transaction times and fewer mistakes, thus further improving overall efficiency. Through these strategic improvements, businesses not only enhance their order fulfillment but also create a more seamless interaction with their customers, ultimately driving growth and success.

Identifying Key Metrics for Measuring Fulfillment Efficiency

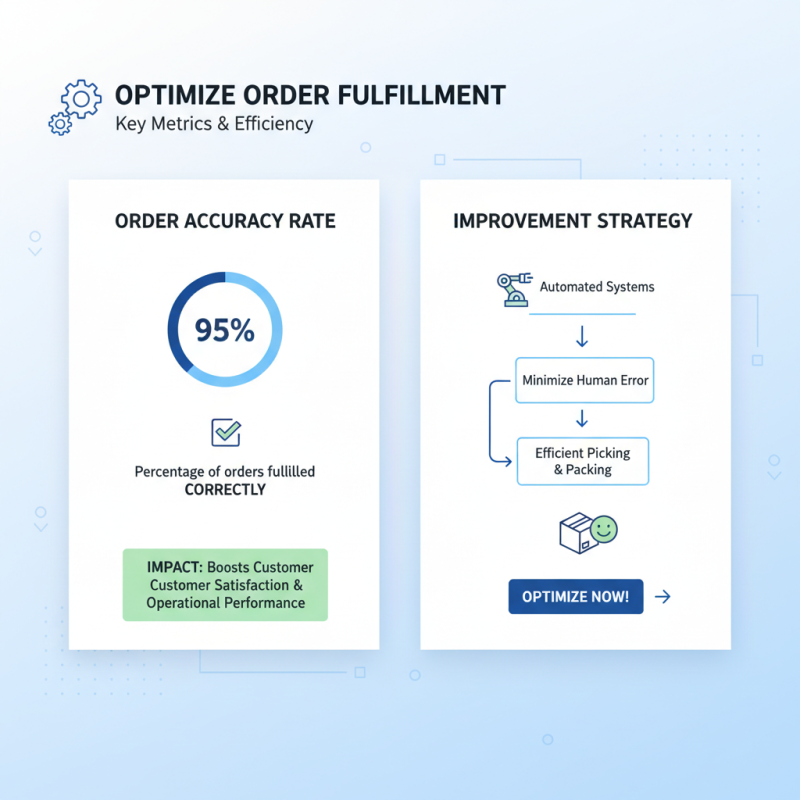

To optimize order fulfillment, it is essential to identify and measure key metrics that directly impact your business efficiency. Start by analyzing order accuracy rates, which reflect the percentage of orders that are fulfilled correctly without errors. This metric not only highlights operational performance but also enhances customer satisfaction. To improve order accuracy, consider implementing automated systems that minimize human errors during the picking and packing process.

Another crucial metric is fulfillment cycle time, which measures the total time taken from when an order is placed until it is delivered to the customer. This metric can spotlight delays and inefficiencies within your operation. To shorten fulfillment cycle times, focus on streamlining processes through techniques like batch processing and optimizing warehouse layout for faster picking. Regularly reviewing and adjusting workflows based on these insights can lead to significant gains in efficiency.

Additionally, keep an eye on inventory turnover rate, indicating how quickly inventory is sold and replaced over a period. A higher turnover indicates efficient inventory management and helps in minimizing storage costs. To boost this metric, adopt just-in-time inventory practices to align stock levels more closely with demand, thus reducing excess inventory and enhancing cash flow. By closely monitoring these key metrics, businesses can discover opportunities for optimization, driving overall efficiency in order fulfillment.

Streamlining Inventory Management to Reduce Order Processing Time

Effective inventory management plays a crucial role in optimizing order fulfillment, as it directly impacts order processing time. According to a report by the Warehouse Optimization Institute, businesses that implement advanced inventory management systems can reduce their order processing time by as much as 30%. Streamlining inventory processes not only enhances efficiency but also improves customer satisfaction through quicker delivery times. By accurately tracking stock levels in real-time and utilizing predictive analytics, organizations can ensure that they maintain optimal stock levels, thereby minimizing backorders and stockouts.

Moreover, integrating technology with inventory management can further expedite the fulfillment process. A survey conducted by the Logistics Management Association found that 67% of companies that automated their inventory tasks cited noticeable improvements in operational efficiency. Automation tools such as barcode scanners and inventory management software allow businesses to efficiently monitor product movement and manage stock replenishment. This not only reduces human error but also frees up valuable staff time, enabling teams to focus on more strategic activities. By prioritizing inventory management and adopting technology solutions, companies can significantly enhance their order fulfillment capabilities, ultimately driving growth and profitability.

Leveraging Technology for Enhanced Order Tracking and Communication

In today’s fast-paced business environment, leveraging technology for enhanced order tracking and communication has become crucial for optimizing order fulfillment. A recent report from McKinsey indicates that companies adopting advanced digital tools improve their order accuracy by up to 20%, significantly impacting customer satisfaction and retention. Real-time tracking allows both businesses and customers to monitor the status of their orders, reducing uncertainty and enhancing transparency. This level of insight fosters trust and encourages repeat purchases, a key indicator of successful fulfillment strategies.

Moreover, optimal communication across the supply chain can substantially enhance operational efficiency. According to a study by Gartner, enterprises with integrated communication systems report a 30% decrease in cycle times for order processing. By utilizing digital platforms for communication, including automated updates and alerts, businesses can streamline interactions between suppliers, warehouses, and customers. Such connectivity not only minimizes delays but also allows for proactive management of potential issues, providing a seamless experience that can significantly boost overall business performance. The integration of these technologies is not just a trend; it's a necessity for companies aiming to remain competitive in an increasingly demanding market.

Top 10 Tips for Optimizing Order Fulfillment to Boost Your Business Efficiency

| Tip Number | Optimization Strategy | Technology Used | Expected Outcome |

|---|---|---|---|

| 1 | Implement Inventory Management Software | Cloud-based Solutions | Reduced stockouts and overstock |

| 2 | Utilize Real-Time Order Tracking | Tracking APIs | Improved customer satisfaction |

| 3 | Automate Fulfillment Processes | Automation Software | Increased operational efficiency |

| 4 | Optimize Shipping Methods | Shipping Management Tools | Cost savings on shipping |

| 5 | Enhance Communication Channels | Chatbots and CRM systems | Better customer engagement |

| 6 | Conduct Regular Performance Analysis | Business Intelligence Tools | Identifying bottlenecks |

| 7 | Implement a Returns Management System | Returns Platforms | Streamlined return process |

| 8 | Leverage Data Analytics for Forecasting | Data Analytics Tools | Improved demand forecasting |

| 9 | Use Mobile Applications for Management | Mobile Apps | Greater flexibility and accessibility |

| 10 | Collaborate with Third-Party Logistics | Logistics Platforms | Scalability in operations |

Implementing Customer Feedback to Improve Fulfillment Strategies

Customer feedback is a vital tool for businesses looking to enhance their order fulfillment strategies. By systematically collecting and analyzing customer insights, companies can identify pain points in their current processes and make informed adjustments. Implementing customer surveys, feedback forms, and direct communication channels allows businesses to gather valuable data on customer satisfaction with delivery speed, accuracy, and overall service. This information serves as a roadmap for optimizing fulfillment processes, ensuring that they align more closely with customer expectations.

Furthermore, regular review of customer feedback not only helps in identifying immediate issues but also fosters long-term improvements. When companies actively demonstrate that they listen to their customers by making necessary changes, they build trust and loyalty. For instance, if customers express concerns about delayed deliveries, businesses can explore logistics partnerships or improve inventory management systems. By prioritizing customer input in the fulfillment strategy, companies not only boost efficiency but also create a more responsive and customer-centric approach that contributes to sustained business growth.

Order Fulfillment Optimization: Customer Feedback Impact

Related Posts

-

Why Effective Supply Chain Management is Crucial for Business Success

-

Why Is Order Fulfillment Critical for Your Business Success?

-

Why Order Fulfillment is Crucial for Your Business Success?

-

2025 Top 5 Trends Shaping the Future of Supply Chain Management

-

Top 10 Warehousing Companies Revolutionizing Supply Chain Efficiency in 2023

-

How to Choose the Best Inventory Solutions for Your Business Needs