Top Supply Chain Management Solutions for Businesses Today?

In today's fast-paced business environment, the complexity of supply chains continues to rise. Companies face numerous challenges that require effective strategies. According to Dr. Lisa Anderson, a renowned expert in supply chain management, "The right supply chain management solutions can turn challenges into opportunities." Her insight highlights the growing importance of tailored solutions in the industry.

Organizations must adapt quickly to market changes, technological advancements, and customer demands. An effective supply chain is not just about logistics; it encompasses every aspect from sourcing to distribution. Many businesses struggle to find the right balance between cost and efficiency. They often overlook the need for integrated solutions that address these evolving needs.

The current landscape demands a proactive approach. Many firms find themselves trapped in outdated systems. This not only hampers growth but also affects customer satisfaction. By embracing innovative supply chain management solutions, companies can enhance their operational effectiveness. This shift is not without challenges, yet it is essential for long-term success in today’s competitive market.

Current Trends in Supply Chain Management Solutions

In today’s rapidly changing business landscape, supply chain management solutions are evolving. Businesses are focusing on automation to enhance efficiency. Automated systems are capable of managing inventory levels effectively. This reduces human errors and creates a smoother workflow. However, reliance on technology can lead to challenges. What if the system fails? Such risks require careful planning.

Another emerging trend is the emphasis on sustainability. Companies are now prioritizing eco-friendly practices within their supply chains. This includes sourcing materials responsibly and reducing waste. While this shift is commendable, it can be costly. Businesses often face higher expenses in the short term. Yet, the long-term benefits could outweigh these initial costs.

Collaboration is also gaining prominence. Companies are increasingly forming strategic partnerships. Sharing resources and data can lead to better decision-making. Still, trust issues may arise among partners. Openness is critical in these relationships. Developing effective communication channels is essential. As businesses adapt, they must remain agile in their strategies. This enables them to respond to changing market demands swiftly.

Top Supply Chain Management Solutions for Businesses Today

| Solution Type | Key Features | Benefits | Current Trends |

|---|---|---|---|

| Cloud-Based SCM | Real-time data access, scalability, integration | Cost-effective, improved collaboration, flexible | Increased adoption due to remote work |

| AI & Machine Learning | Predictive analytics, demand forecasting | Enhanced decision-making, reduced lead times | Rise in automation and optimization technologies |

| Blockchain Solutions | Transparency, traceability, security | Increased trust, reduced fraud | Growing popularity in food and pharmaceutical sectors |

| IoT Integration | Connected devices, real-time tracking | Improved inventory management, enhanced visibility | Advancement in smart logistics |

| Robotic Process Automation | Automated repetitive tasks, workflow optimization | Increased efficiency, cost reduction | Integration with AI for smarter automation |

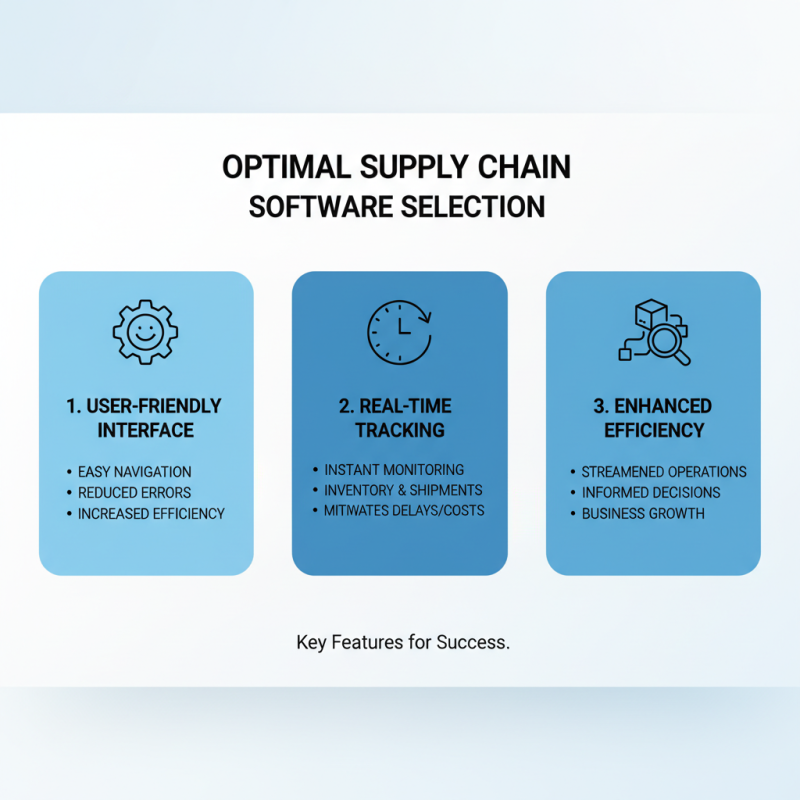

Key Features to Look for in Supply Chain Software

When choosing supply chain software, businesses should focus on key features that enhance efficiency. A user-friendly interface is essential. Employees need to navigate the software easily. Complexity can lead to mistakes and inefficiencies. Real-time tracking is also vital. Companies want to monitor their inventory and shipments instantly. Delays can cost a lot, both financially and reputationally.

Integration with existing systems is crucial. Many businesses have legacy systems in place. New software must work seamlessly with these. Poor integration can result in data silos and miscommunication. Customization options are beneficial too. Every business has unique needs. A one-size-fits-all solution often falls short. Companies should reflect on their specific requirements before making a choice.

Lastly, strong analytical tools are important. These can provide insights into operation trends. Data-driven decisions help optimize the supply chain. Relying solely on intuition can be risky. It's critical to evaluate the long-term impact of the software. Addressing these points ensures better supply chain management.

Top Supply Chain Management Technologies for Business Optimization

In today's fast-paced business landscape, supply chain management technologies are crucial for optimization. Companies increasingly rely on data analytics to drive efficiency. By analyzing real-time data, businesses can anticipate demand fluctuations. This improves inventory management and reduces waste.

Cloud-based solutions are pivotal for modern supply chains. They enable seamless collaboration among stakeholders. Transport logistics can be streamlined with advanced tracking systems. Yet, integration with existing systems often poses challenges. Organizations must invest time and resources to overcome these hurdles.

Automation is also transforming supply chain operations. Robotics and AI enhance warehousing processes, promoting speed and accuracy. However, dependence on technology can lead to vulnerabilities. Cybersecurity threats require constant vigilance. Businesses must find a balance between innovation and risk management.

Comparative Analysis of Leading Supply Chain Management Providers

In today's complex business environment, choosing the right supply chain management solution can be challenging. Each provider offers unique features, focusing on different aspects of the supply chain. Some excel in inventory management, while others shine in analytics capabilities. Organizations must weigh these factors carefully.

When comparing leading solutions, it becomes evident that integration is key. Systems that seamlessly connect suppliers, manufacturers, and customers provide significant advantages. However, some companies find integration difficult. They struggle with data silos and outdated processes. This inefficiency can lead to costly mistakes.

Performance benchmarks are essential in this analysis. Some providers may claim impressive metrics but fail to deliver in practice. It's crucial for businesses to conduct thorough research and pilot programs. They must remain vigilant and question the claims made by different providers. This reflective approach will help organizations select a solution that truly meets their needs.

Best Practices for Implementing Supply Chain Management Solutions

Implementing effective supply chain management solutions requires careful planning and attention to detail. First, businesses must assess their current processes. A thorough analysis can reveal bottlenecks and inefficiencies. Gathering input from employees across departments can provide valuable insights. This input helps create a more comprehensive understanding of the supply chain dynamics.

Training staff is essential for a successful implementation. Workers need to understand how new solutions will impact their roles. Engaging them early can ease resistance to change. Furthermore, establishing key performance indicators can help track progress. Setting realistic goals is critical. Achieving these goals may require adjustments along the way. Not every solution will fit all scenarios perfectly.

Regular feedback loops should be part of the implementation. Listening to frontline workers can uncover unforeseen challenges. This approach also fosters a culture of continuous improvement. It’s important to remember that no system is perfect from the start. Constant revisions and updates may be necessary to meet evolving market demands. With persistence and adaptability, any business can strengthen its supply chain.

Related Posts

-

Top 10 Best Logistics Websites for Efficient Supply Chain Management

-

Understanding Order Fulfillment Services: Key Benefits and Best Practices

-

Top 10 Inventory Management Solutions to Streamline Your Business Operations

-

10 Essential Tips for Effective Logistics and Supply Chain Management?

-

Top 10 Warehousing Companies Revolutionizing Supply Chain Efficiency in 2023

-

Why Order Fulfillment is Crucial for Your Business Success?