Top 10 Warehousing Companies Revolutionizing Supply Chain Efficiency in 2023

In the rapidly evolving landscape of logistics and supply chain management, warehousing companies play a pivotal role in enhancing operational efficiency and fulfilling customer demands. As we navigate through 2023, the strategies employed by these companies are changing the way goods are stored, processed, and delivered. Industry expert Dr. Helen Grant, a leading figure in supply chain innovation, emphasizes, "The future of warehousing lies in technology and sustainability, shaping how we manage our resources and meet consumer expectations."

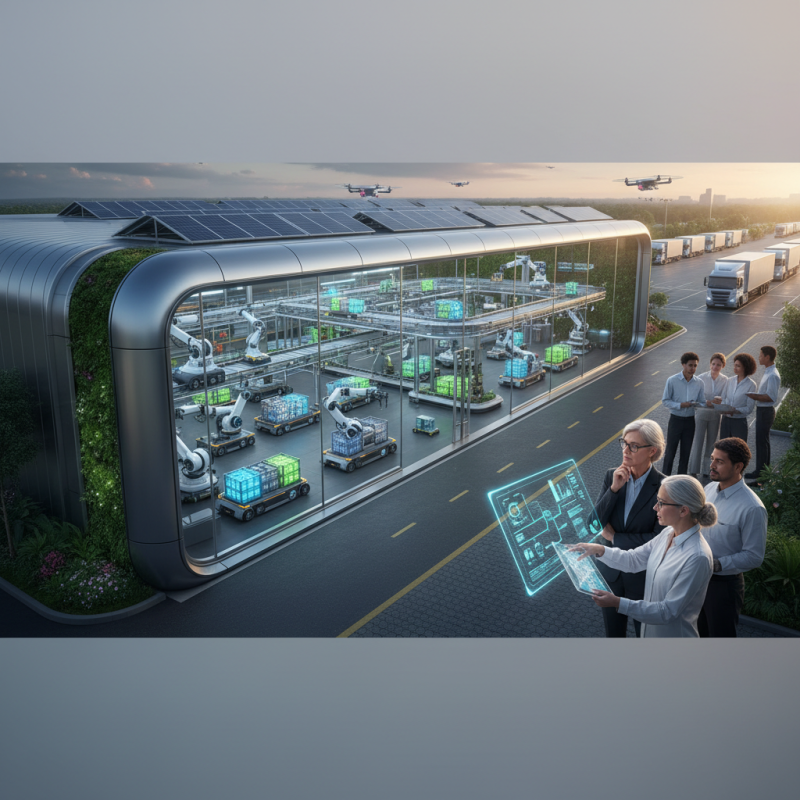

Today’s warehousing companies are not just about storing products; they are becoming dynamic hubs of activity that leverage advanced technologies such as automation, data analytics, and artificial intelligence. These innovations enable companies to optimize their processes, reduce costs, and improve service levels. As businesses face unprecedented challenges such as fluctuating market demands and supply chain disruptions, the adaptability and efficiency of warehousing solutions have never been more essential.

This article delves into the top ten warehousing companies that are revolutionizing supply chain efficiency in 2023. By examining their cutting-edge methods and contributions to the industry, we will uncover how these organizations are setting new benchmarks for efficiency and sustainability, ultimately redefining the future of warehousing.

Overview of Warehousing in the Modern Supply Chain

The modern supply chain is increasingly reliant on efficient warehousing solutions, which serve as critical hubs for inventory management and distribution. According to a report by Grand View Research, the global warehousing market is projected to reach $625.5 billion by 2026, exhibiting a compound annual growth rate (CAGR) of 13.4%. This rapid growth highlights the importance of warehouses in not only storing goods but also in enhancing supply chain agility and responsiveness. As demand fluctuations become more pronounced, warehouses are integrating advanced technologies such as automation and artificial intelligence to streamline operations and reduce lead times.

Moreover, the impact of e-commerce continues to shape warehousing strategies, with JDA Software noting that 80% of companies are prioritizing investments in their warehouse infrastructures to improve order fulfillment speed. Modern warehouses are increasingly adopting practices such as cross-docking and real-time inventory tracking to meet the expectations of a fast-paced market. The integration of Internet of Things (IoT) devices is also revolutionizing inventory management, allowing for better visibility and control along the supply chain. As businesses navigate these changes, the role of warehousing remains pivotal in driving overall supply chain efficiency, ultimately influencing customer satisfaction and retention.

Key Factors Driving Supply Chain Efficiency in 2023

In 2023, the warehousing sector is experiencing a transformative shift that significantly enhances supply chain efficiency. A report from the Council of Supply Chain Management Professionals highlights that companies leveraging automation and advanced technologies have seen productivity gains of up to 30%. This drive for efficiency is largely fueled by the adoption of warehouse management systems (WMS) and artificial intelligence (AI), which streamline operations by optimizing inventory management and improving order fulfillment processes.

Moreover, flexibility and sustainability have emerged as crucial factors in supply chain effectiveness. Research from McKinsey & Company indicates that firms implementing sustainable practices in their supply chains can reduce operational costs by as much as 20% while meeting growing consumer demand for eco-friendly initiatives. Additionally, adopting a multi-channel distribution strategy allows companies to respond rapidly to market changes, ultimately leading to enhanced customer satisfaction. The convergence of these elements not only revolutionizes traditional warehousing practices but also positions companies to thrive in a dynamic market landscape.

Innovative Technologies Transforming Warehousing Practices

In 2023, the landscape of warehousing has been dramatically transformed by innovative technologies reshaping supply chain efficiency. Automation and robotic systems have become mainstream, enhancing operational speed and accuracy. According to a report by Allied Market Research, the global warehousing market is expected to grow significantly, with automation solutions predicted to account for over 50% of the industry's value by 2025. This surge is driven by the need for faster turnaround times and reducing labor costs, making automation a critical component for companies aiming to stay competitive.

One notable trend is the integration of artificial intelligence (AI) in inventory management. AI technologies enable smarter forecasting and inventory optimization, allowing companies to reduce overstock situations and minimize stockouts. A study from McKinsey indicates that firms implementing AI in their warehousing operations can boost inventory accuracy by up to 30%, significantly improving supply chain responsiveness.

Tips: Implementing a robust warehouse management system (WMS) can streamline operations and maximize efficiency. Regularly train your staff on new technologies to ensure they are adequately prepared to utilize advanced tools. Lastly, consider adopting a data-driven approach to decision-making; analyzing your warehousing operations can uncover valuable insights that lead to continuous improvement.

Profiles of the Top 10 Warehousing Companies in 2023

In 2023, the landscape of warehousing companies is marked by significant innovations that enhance supply chain efficiency. The rise of automation and advanced technology has allowed these companies to streamline operations, significantly reducing order processing times. According to a recent industry report by Logistics Management, adoption of advanced technologies such as Artificial Intelligence (AI) and Internet of Things (IoT) in warehousing has the potential to boost operational efficiency by up to 30%. Companies are increasingly implementing real-time inventory tracking systems, which contribute to improved accuracy and reduced holding costs.

Furthermore, the emphasis on sustainable practices has also reshaped the priorities of leading warehousing firms. A study from the Warehousing Education and Research Council (WERC) indicates that more than 65% of companies are now prioritizing energy efficiency and waste reduction within their warehouses. This shift toward sustainability not only meets regulatory requirements but also enhances brand reputation among eco-conscious consumers. As these top companies focus on integration of renewable energy sources and efficient waste management practices, they are setting new standards for operational excellence, proving that efficiency and sustainability can go hand-in-hand in the modern supply chain.

Top 10 Warehousing Companies Revolutionizing Supply Chain Efficiency in 2023

This chart illustrates the efficiency ratings of various warehousing companies in 2023, focusing on key metrics such as inventory turnover, order accuracy, and delivery speed. The data reflects the latest trends in the warehousing industry, showcasing how companies are enhancing supply chain performance.

Future Trends in Warehousing and Supply Chain Optimization

The landscape of warehousing and supply chain management is undergoing significant transformation in 2023, driven by technological advancements and evolving consumer demands. One of the key trends shaping this future is the integration of artificial intelligence and machine learning into warehouse operations. These technologies enable better inventory management by predicting stock levels, optimizing storage layouts, and enhancing order fulfillment processes. As a result, companies are not only reducing operational costs but also improving accuracy and speed, allowing them to meet the rising expectations of consumers for timely deliveries.

Another notable trend is the adoption of automation and robotics within warehouse environments. Automated systems are streamlining repetitive tasks, such as picking and packing, thus freeing up human resources for more strategic roles that require critical thinking and problem-solving skills. Additionally, the implementation of advanced warehouse management systems (WMS) is paving the way for greater visibility and real-time tracking throughout the supply chain. This heightened level of transparency is essential for making informed decisions and improving collaboration among different stakeholders in the supply chain, ultimately leading to enhanced efficiency and responsiveness in a fast-changing market.

Related Posts

-

Why Is Order Fulfillment Critical for Your Business Success?

-

Top 10 Best Logistics Websites for Efficient Supply Chain Management

-

How to Start a Successful Logistics Business in 2023 Tips and Strategies

-

2025 Top Logistics Business Trends and Digital Innovations to Watch

-

Why Effective Supply Chain Management is Crucial for Business Success

-

10 Essential Tips for Choosing the Right Logistics Partner for Your Business